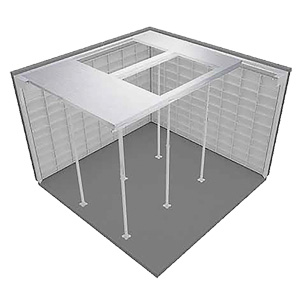

Build concrete walls more efficiently

Ensure more agility, economy and reduction of inputs, using the combination of Atex products to build concrete walls. With them, you will also have a personalized design in the finish, without the need for plastering or repairs.

Check out all the benefits of this construction system.

Speed

The simple assembly of the moulds can result in a construction cycle of up to one day. It is a great time saver compared to other construction systems that have cycles of 7 to 10 days.

Versatility

The panels can be moved from one floor to the next through openings in the slab, without the need for cranes.

Easy to assemble

Because it is simple to assemble, this product does not require the hiring of specialized labor or carpenters.

Durability

The moulds are manufactured with 6061-T6 aluminum alloy. So they can be reused hundreds of times.

Security

It does not require the removal of props and heads of props when dismantling the slab panels.

Quality finish

As the panels are precisely sized, they generate smoother finishes. Thus, there is no need for plastering and repair after concreting.