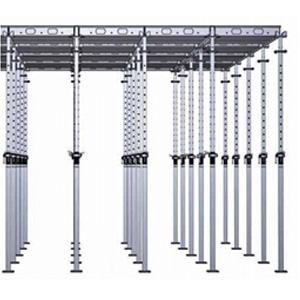

Discover the advantages of the rib canceller

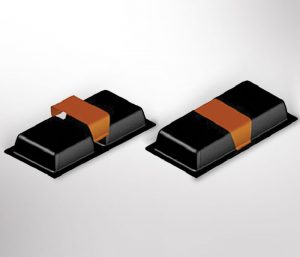

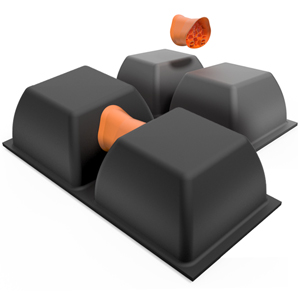

The Atex rib canceller is a resistant and precise piece. It fits perfectly between the bidirectional moulds for ribbed slab and maintains its position during concreting.

The end result is the construction of a unidirectional ribbed slab, guaranteeing more agility, practicality and economy during this process. It can be used with the mould families Atex610U, Atex640U, Atex 655U, Atex 685U, Atex 755U, Atex 800U, Atex 830U and Atex 875U.

Talk to our experts and request a quote for your project.